Pioneering Tru-Trac intelligent belt scale launched at bauma 2025

Tinus Ludik Sales Manager - Bulk Materials Handling Division at Tru-Trac

More than a belt scale, Tru-Trac’s latest innovation provides complete conveyor health insights and anomaly detection

The next-generation Tru-Trac belt scale combines cutting-edge AI, diagnostics and automation for industry-leading performance

Real-time load cell monitoring is key, continuously tracking millivolt (mV) signals to maintain perfect balance and prevent faults

AI-powered calibration eliminates manual recalibration with Tru-Trac’s self-adjusting belt scale for continuous precision measurements

The next-gen Tru-Trac belt scale harnesses AI, smart diagnostics and automation for unmatched accuracy and performance

This article has been supplied.

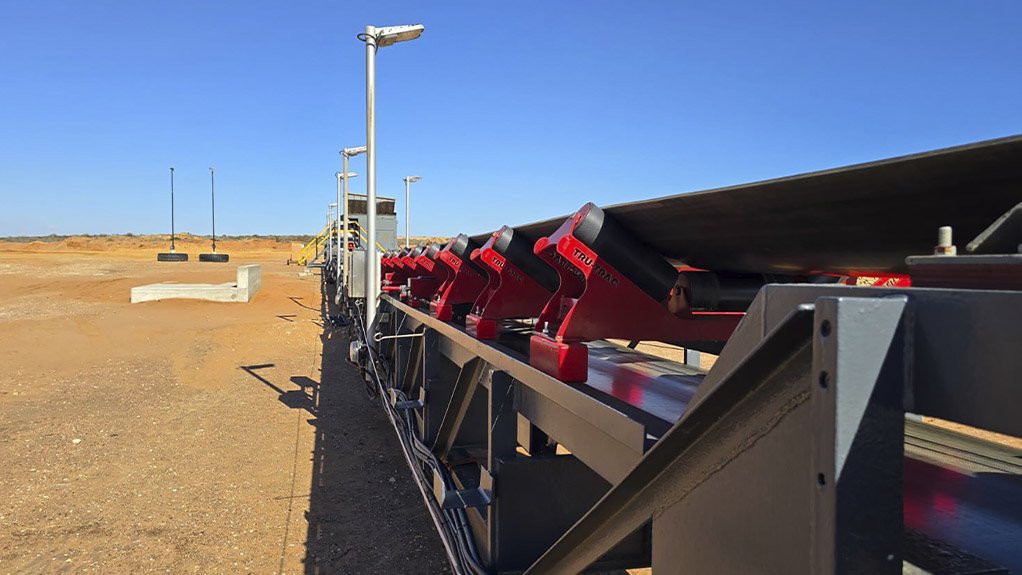

In an era where data-driven decisions are critical, Tru-Trac Rollers unveiled its intelligent belt scale system at bauma 2025. Featuring integrated AI-driven continuous calibration checking and real-time load cell monitoring with traditional belt scales, this next-generation solution goes beyond measuring tonnes per hour (tph) to deliver advanced conveyor belt monitoring.

Integrating seamlessly with the award-winning Rip Prevent+ system, which Tru-Trac debuted to its African customers at Electra Mining Africa 2024, this innovation leverages artificial intelligence (AI) to detect anomalies or rip events on all conveyor belt types including steel cord, pipe, and fabric belts.

“This intelligent belt scale sets a new standard,” says Tinus Ludik, Sales Manager – Bulk Materials Handling Division at Tru-Trac. “It is not just technologically advanced but also user-friendly, providing unprecedented data that conventional belt scales simply don’t offer.”

A standout feature is real-time load cell monitoring ensuring millivolt (mV) signals remain within optimal range. Any deviations trigger proactive warnings, allowing for timely intervention and reducing the risk associated with inaccurate or inconsistent readings. By continuously assessing load cell health, the system enhances reliability, repeatability, and accuracy.

Unlike traditional systems that require manual recalibration, Tru-Trac’s intelligent belt scale automatically detects and corrects inaccuracies. Advanced AI algorithms analyse and cross check the belt scale readings against mass flow measurements, identifying deviations and self-adjusting to maintain precise measurements. This eliminates the need for manual intervention, improves reliability and reduces maintenance.

Beyond weighing, the system also monitors conveyor health, ensuring consistent material flow. Continuous mV readings assess belt alignment, flagging potential misalignment caused by off-centre loading.

The belt scale doesn’t just focus on immediate accuracy - it delivers valuable long term operational insights. By tracking key performance indicators (KPIs) in real time, customers gain a deeper understanding of plant efficiency and productivity trends.

“The system’s anomaly detection continuously analyses operational parameters,” adds Ludik. “If any irregularities arise they are flagged instantly, allowing for corrective action before small issues escalate. This real-time oversight fosters constant optimisation and operational excellence.”

With its groundbreaking combination of AI-driven automation, real-time monitoring and advanced diagnostics, Tru-Trac’s intelligent belt scale is set to redefine conveyor performance.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation